WHAT IS EVERCURE?

One of the greatest assets of Everlast, and what sets us apart is the Evercure Process. This process includes the revolutionary CECI® enhancement that not only seals the metal’s cut edge, but also protects it from both natural and commercial corrosive elements. Everlast’s panels are stronger, more durable and less likely to crack over time. The Evercure Process is state-of-the-art and we are confident it will continue to set the standard for quality metal building components.

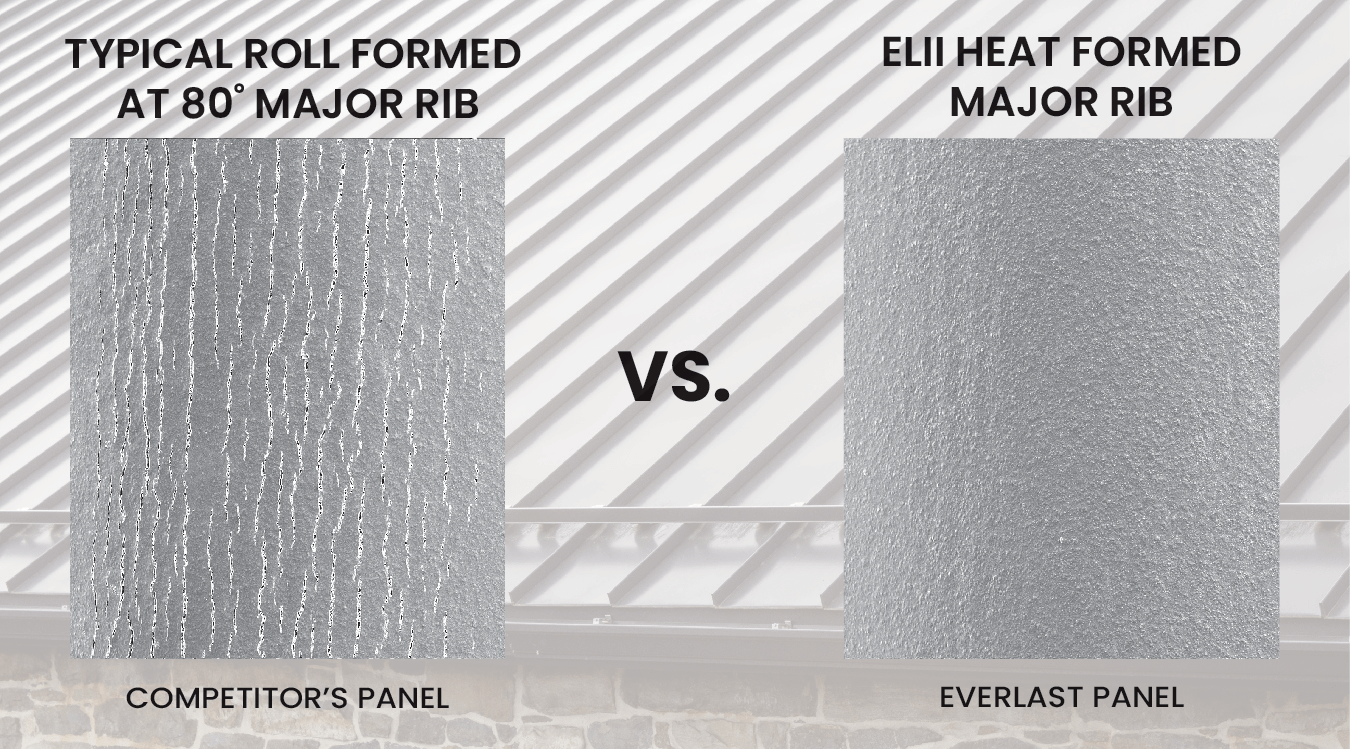

Heat Forming

Why does Everlast Heat Form? Cracks allow moisture, which is often contaminated by atmospheric pollutants, to penetrate the protective surface of the coating, and cause the substrate to rust and corrode. In fact, the fracture in the paint can cause a painted panel to corrode at a faster rate than an unpainted panel. At the point where the paint film has been exposed electrochemical cells are established which will promote greater and faster corrosive attack. The result is accelerated corrosion at these areas because of their tendency to remain wet longer.

The Heat Formed panel creates a more flexible paint system which is better able to withstand the rigors of the forming process. The paint coverage is not compromised and the result is an outstanding barrier protection. This barrier protection prevents corrosion by isolating the steel from the environment.

The photos show how Everlast’s Heat Forming panel outlasts the competitors panel. The Heat Formed panel creates a paint system that is more flexible and therefore better able to withstand the rigors of the forming process. The paint coverage is not compromised and the result is outstanding barrier protection. This barrier protection prevents corrosion by isolating the steel from the environment.

ADVANCED TOOLING

Advanced State-of-the-Art Tooling is another area of excellence in Everlast Roofing’s roll formed products. Using additional stands places less stress on the formed radius of our panel providing for the most consistent panel profile on the market.

CECI®

At Everlast, we have been working on a way to protect the cut edge of our manufactured steel panels. After committing to buying only the best steel on the market, and innovating the traditional roll forming process with Heat Forming, we went even further with the last step in our Evercure process. This application is being applied to a factory cut edge of all Everlast II®, PBR, and “A” Panels. Because the corrosion inhibitor applied is a clear product, end-users will see virtually no sign of CECI®. It works to protect against and effectively decrease corrosion rates, as proven through industry research. Our goal at Everlast Roofing, Inc. is to provide cut-edge technological advances to our products to ensure the highest standard of quality. CECI® is just another step in our commitment of bringing to the metal marketplace, only the finest materials in quality building components.

FINISHED PANEL

As proven through industry research, Everlast’s panels are stronger, more durable and less likely to crack over a duration of time.